Main content

Caterpillar

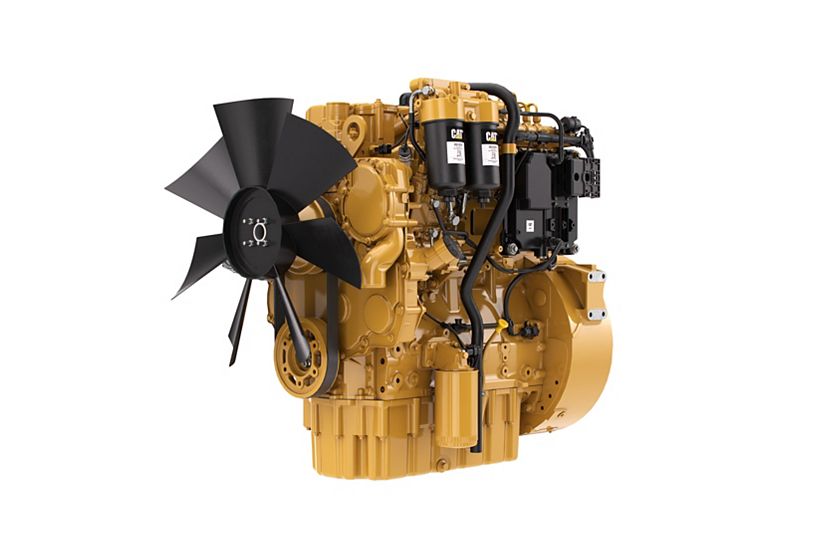

Cat?� C4.4 Diesel Engine

Cat?� C4.4 Industrial Diesel Engines offer the perfect balance of durability, fuel efficiency and low emissions. Extensively tested on the job, these engines use a range of Common Rail fuel systems and advanced control systems to deliver maximum uptime in the harshest environment. They have proven they can handle the toughest applications and deliver superior performance that exceeds the expectations of the most demanding users. Industries and applications powered by C4.4 engines include: Agriculture, Aerial Lifts, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Feller Bunchers, Forestry, Forklifts, General Industrial, Harvesters, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Sweepers, Paving Equipment, Pumps, Skidders, Specialty Ag Equipment, Sprayers, Trenchers, Turf and Landscaping and Underground Mining Equipment. C4.4 engines, with ratings: 74.5-106 kW (100-142 hp) @ 2200 rpm, meet EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Media

Photos

360° View

Exterior

360° Exterior view. Double click on the image to zoom in on any area of the product.

Details

Specifications

Power Rating

| Spec | Value |

|---|---|

| Maximum Power | 142 hp 106 kW |

| Maximum Torque | 411.2 lb-ft @ 1400 rpm 558 Nm @ 1400 rpm |

| Rated Speed | 2200 rpm 2200 rpm |

| Minimum Power | 91.2 hp 68 kW |

Emission Standards

| Spec | Value |

|---|---|

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

General

| Spec | Value |

|---|---|

| Engine Configuration | Inline 4, 4-Stroke-Cycle Diesel Inline 4, 4-Stroke-Cycle Diesel |

| Bore | 4.1 in 105 mm |

| Stroke | 5 in 127 mm |

| Displacement | 269 in³ 4.4 l |

| Compression Ratio | 16.9:1 16.9:1 |

| Aspiration | Turbocharged (T) or Turbocharged Aftercooled (TA) Turbocharged (T) or Turbocharged Aftercooled (TA) |

| Combustion System | Direct Injection Direct Injection |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Aftertreatment | - - |

Engine Dimensions - Approximate

| Spec | Value |

|---|---|

| Length | 24.8 in 631 mm |

| Width | 24.6 in 626 mm |

| Height | 37.7 in 958 mm |

| Weight – Net Dry – Basic Operating Engine Without Optional Attachments | 794 lb 360 kg |

Standard Equipment

Air Inlet System

- Inlet manifold with choice of inlets.

Control System

- Alternator

- Starter motor

- Glow plug starting aid

Flywheels and Flywheel Housing

- SAE No. 3 flywheel housing

- Flywheel and starter rings

Fuel System

- Fuel filter positions

Lube System

- Lubricating oil filters and breathers

- Oil filter positions

- Lube oil sump

Power Take Off

- SAE B Power Take Off (PTO)

General

- Paint: Caterpillar yellow, with optional colors available at request

- Timing case and gear-driven auxiliaries

- Belt-driven auxiliaries

- Engine mountings

- Gauges

- Displays

- Power and torque curve tailoring