Main content

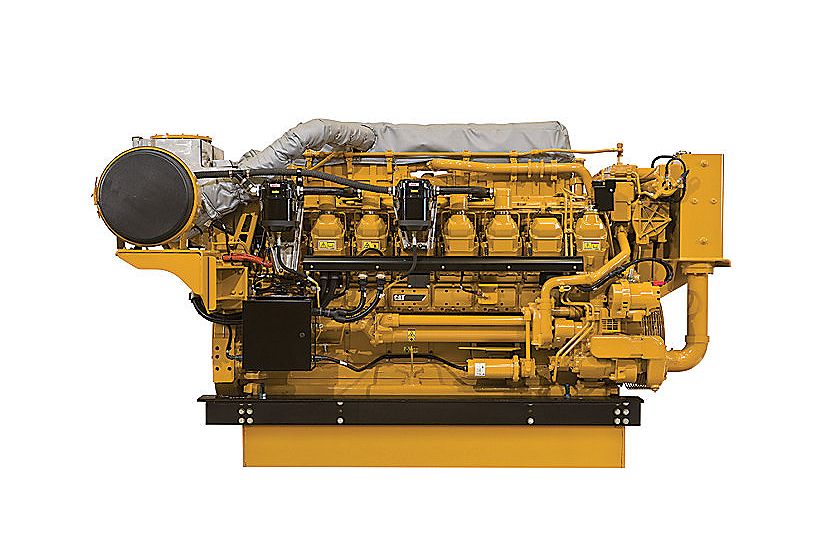

Caterpillar

3516C

The Cat® 3516C marine propulsion engine delivers results under hard working conditions. This engine family is designed to maximize the performance of your invested dollars with a wide range of available power ratings, standard and reverse rotation configurations, no required aftertreatment, and efficient fuel consumption. This engine is available as IMO II or China Stage II emissions compliant making it an excellent propulsion engine choice for Tug, Governmental, and other workboat applications.

Media

Photos

Details

Specifications

Power Rating

| Spec | Value |

|---|---|

| Power Range | 2000-3385 bhp (1492-2525 bkW) 2000-3385 bhp (1492-2525 bkW) |

Engine Specifications

| Spec | Value |

|---|---|

| Speed Range | 1200-1800 rpm 1200-1800 rpm |

| Emissions | IMO II IMO II |

| Aspiration | TTA TTA |

| Bore | 8.46 in 215 mm |

| Stroke | 7.48 in 170 mm |

| Displacement | 4765 in³ 78 l |

| Rotation from Flywheel End | Counterclockwise or Clockwise Counterclockwise or Clockwise |

| Configuration | V 16, 4-Stroke-Cycle Diesel V 16, 4-Stroke-Cycle Diesel |

Dimensions & Weights

| Spec | Value |

|---|---|

| Minimum Height | 77.4 in 1967 mm |

| Maximum Length | 148 in 3761 mm |

| Maximum Width | 84.3 in 2142 mm |

| Minimum Length | 143.1 in 3637 mm |

| Maximum Height | 84.6 in 2150 mm |

Standard Equipment

Air Inlet System

- Corrosion resistant separate circuit freshwater aftercooled, powercore air cleaner

Control System

- Dual Caterpillar® A3 Electronic Control Unit (ECU) LH with electronic unit injector fuel system rigid wiring harness (10 amp DC power required to drive ECU)

Cooling System

- Gear-driven centrifugal auxiliary sea water pump, geardriven centrifugal jacket water pump, expansion tank for commercial engines, coolant shunt tank on lightweight engines, engine oil cooler, thermostats and housing.

ECU Functions

- Programmable low idle, SAEJ1939 data link, Cat® data link, engine diagnostics, general alarm relay, programmable parameters (system application and tattletales), Caterpillar ET service tool interface, remote shutdown, shutdown notify, load feedback, overspeed shutdown, overspeed verify

Exhaust System

- Dry gas-tight exhaust manifolds with heat shields, dual turbochargers with watercooled bearings and heat shield. Wastegate on select ratings

Fuel System

- Electronically controlled unit injectors, simplex fuel filter (RH) with service indicators, fuel transfer pump

Instrumentation

- Marine Power Display of: Engine oil pressure, engine water temperature, fuel pressure, engine speed, fuel consumption, overspeed shutdown notification light, prelube and shutdown override

Lube System

- Gear-driven pump, top-mounted dual crankcase breather groups, simplex oil filter, oil filler and dipstick

Power Take-Offs

- Accessory drive, two-sided front housing

Protection System

- Emergency stop pushbutton, safety shutoff, oil pressure, and water temperature

General

- Two lifting eyes mounted to cylinder heads, Caterpillar yellow paint, parts books and maintenance manuals, shrink-wrap.

ISO Certification

- Factory-designed systems built at Caterpillar ISO 9001:2000 certified facilities.

Optional Equipment

Air Inlet System

- Air Cleaner Removal

- Remote Air Inlet Adapters

Charging System

- Battery Chargers

- Charging Alternators

Control System

- Throttle Position Sensor

- Throttle Synchronization

Cooling System

- Water Level Switch Gauge

- Coolant Level Sensors

- Connections

- Keel Cooling Conversions

- Heat Exchangers

- Auxiliary Water Pumps

- Sea Water Pump Removal

- Coolant Shunt Tanks

- Air Separator

- Marine Gear Cooling

Exhaust System

- Exhaust Outlet

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

Fuel System

- Fuel Cooler

- Fuel Priming Pumps

- Flexible Fuel Lines

- Rigid Fuel Lines

- Primary Fuel Filter

- Fuel level switch

Instrumentation

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface

- Thermocouples

- Remote Panel Display

- Remote Cylinder Temperature Display

- Pilot House Instrument Panels

- Marine Gear Sensors

- Engine Vision Display System

Lube System

- Oil Pan

- Oil Pan Accessories

- Sump Pumps

- Prelubrication Options

- Lubricating Oil

- CENTRIFUGAL OIL FILTER

Mounting System

- Engine Supports

- Vibration Isolation Mountings

Power Take-Offs

- Flexible Coupling and Guards

- Front Housing Accessories

- Upper Left Hand Front Location:

- Upper Right Hand Front Location:

- Upper Right Hand Rear Location:

- Lower Left Hand Front Location:

- Lower Left Hand Rear Location:

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take Offs

- Crankshaft Pulleys

- Damper Guard Removals

Protection System

- Air Inlet Shutoffs

- Switches and Contactors

- Explosion Relief Valve

- Sensors

Spare Parts Kits

- Parts Kits

- Pump Kits

- Fuel Transfer

- Lube Oil

Special Appearance

- Chrome Plated Relief Valves

- Black Air Cleaners

Starting System

- Starting Motors or Barring Device

- Air Starting Motors Options

- Starting Aids

- Battery Sets – 24 Volt – Dry

- Battery Rack

General

- Tool Set

- Caterpillar Datalink Wire