Main content

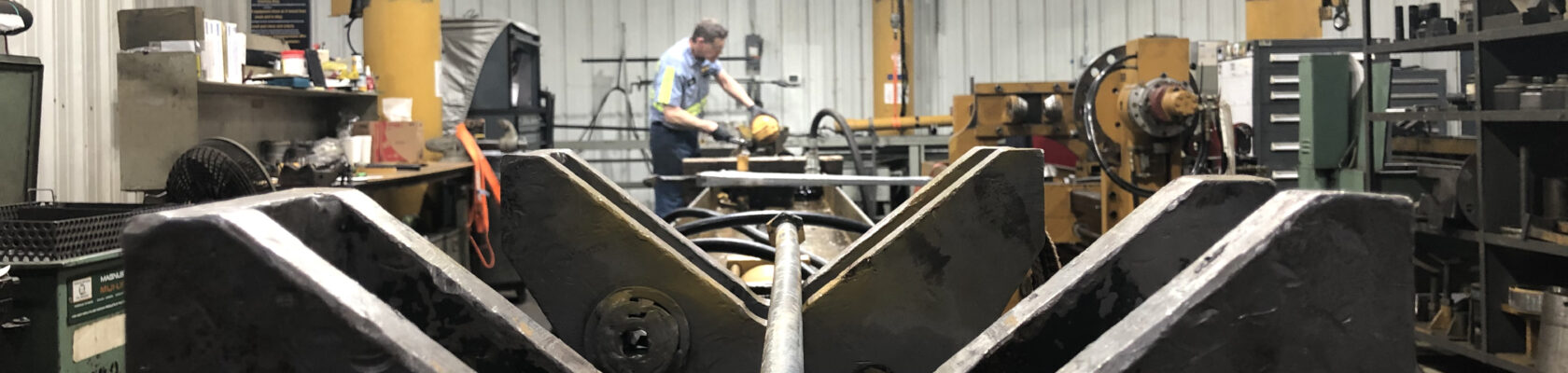

Hydraulic Service

Hydraulic systems are essential to the operation of all types of equipment. That’s why the Riggs Cat full-service industrial machine shop offers a complete range of hydraulic services to help you get the most out of your equipment fleet.

As the authorized Cat® dealer for the region, our combination of top-quality products and superior parts and service capabilities can’t be matched. Contact your nearest branch to learn more.

Hydraulic Service Capabilities

Cylinders and Rods

Riggs provides all services required to maintain or repair hydraulic cylinders and rods, including:

- Honing capabilities up to 12” diameter x 16’ length

- Torquing up to 40,000 lbs.

- Custom cylinder fabrication

- Repairing and rebuilding rods and cylinder tubes

- OEM re-manufacturing cylinder components

- Re-tube cylinders

- Exchange cylinder inventory

- Disassembly and assembly benches at all locations

- Induction hardened chrome rod stock in inventory

Hydraulic Hose Service

Each Riggs location offering hydraulic repair in Arkansas has state-of-the-art Cat hose presses to ensure you receive quality workmanship.

All of our hoses are:

- Assembled by certified technicians

- Visually and dimensionally checked

- Cleaned to remove contaminants

- Capped

Our hose parts inventory is informed by client requirements to ensure a comprehensive collection. Riggs stocks nearly 4,000 line items – a total of over 10,000 pieces – statewide.

Pumps and Motors

Hydraulic services on pumps and motors include:

- Service for a wide range of makes

- Tear down, inspection and failure analysis

- Complete repair and reconditioning

- Full load and pressure testing

- Hydraulic hammer repair

- OEM re-manufactured components

- OEM new replacement

- Pump and motor-based rebuilds

Hydraulic Testing

All components that Riggs Cat rebuilds or refurbishes are tested to ensure reliability and longevity.

Riggs technicians:

- Will not send a cylinder, pump or motor back to the field without performance testing.

- Pressure test hydraulic cylinders at normal system pressure – not just testing the seal.

- Use the pump and motor test bench, allowing the simulation of machine or system.

Contamination Control

The Riggs Cat Little Rock hydraulic facility is climate controlled to minimize contamination. Current hydraulic systems are designed with ultra-tight specifications, which means that any intrusion by contaminates can cause failures or reduce system life. Riggs has stringent standards of cleanliness in order to minimize, with the intent to eliminate, component-killing contaminates.

Valves

The Riggs Cat team has the knowledge, parts and repair capabilities to save you time and money on your construction equipment valves. An extensive selection of valves and related parts are in stock to ensure fast turnaround. All parts are tested before re-installation to ensure proper execution of hydraulic repairs.