Main content

Caterpillar

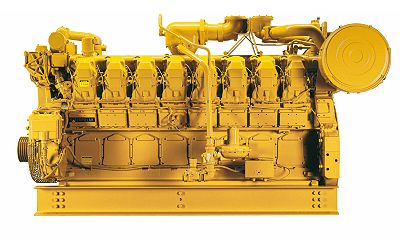

G3516J Gas Engine

The line of G3500 engines brings versatility, uptime, and low operating cost to your gas compression operation. They are equipped with ADEM A3 technology that enables highest performance and safety while maintaining low emissions. Ideal applications for G3500 engines include gas lift, gas gathering, and wellhead gas compression. The Cat G3516J gas engines are rated at 1029 bkW (1380 bhp) @ 1400 rpm and are NSPS site compliant capable with customer-provided air-fuel ratio control and aftertreatment.

Media

Photos

Details

Specifications

Engine Specifications

| Spec | Value |

|---|---|

| Emissions | U.S. EPA Spark Ignited Stationary NSPS emissions U.S. EPA Spark Ignited Stationary NSPS emissions |

| Minimum Rating | 1380 BHP 1029 bkW |

| Maximum Rating | 1380 BHP 1029 bkW |

| Displacement | 4211 in³ 69 l |

| Aspiration | Turbocharged-2 Stage aftercooled Turbocharged-2 Stage aftercooled |

| Oil Change Interval | 1000 hrs 1000 hrs |

| Stroke | 7.5 in 190 mm |

| Bore | 6.7 in 170 mm |

| Combustion | Lean Burn Lean Burn |

| Governor | Electronic (ADEM A3) Electronic (ADEM A3) |

| Lube Oil System | 423 L (112 gal) 423 L (112 gal) |

Standard Equipment

Air Inlet System

- Axial flow air cleaners

- Single element canister type with service indicator

Cooling System

- Two-stage charge air cooling system

- Engine cooling and charge air cooling thermostats

Exhaust System

- Watercooled exhaust manifolds

- Dry Turbocharger housings

- Water-cooled exhaust elbow

Flywheels & Flywheel Housings

- SAE No. 00 flywheel housing

- SAE standard rotation

- SAE No. 21 Flywheel

Fuel System

- 7-40 psig gas supply

- Electronic fuel metering valve

- Gas pressure regulator

- Gas shutoff valve

- Fuel System

Instrumentation

- Remote-mounted Advisor control panel

- Interconnect harness

Lubrication System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — shallow

- Oil sampling valve

- Turbo oil accumulator

Mounting System

- Rails

Protection System

- Electronic shutoff system

- Gas shutoff valve

General

- Paint — Cat yellow

- Crankshaft vibration damper and guard

Power Take Offs

- Front lower LH accessory drive

- Front housing, two sided

Optional Equipment

Air Inlet System

- Remote air inlet adapters

- Rain Shield

Charging System

- CSA Alternator (24V, 65A)

Exhaust System

- Flexible fittings

- Elbows

- Flange

- Mufflers

Fuel System

- Fuel filter

Lubrication System

- Oil bypass filter

- Deep sump oil pan

- Air prelube pump

- Lubricating oil

- Oil pan drain

Power Take-Offs

- Front stub shaft

Protection System

- Explosion relief valves, status control box interconnect wiring harness

Starting System

- 90 psi starter

- 150 psi starter

EU Certification

- EEC DOI certification

G3516 NA

G3516 NA