Main content

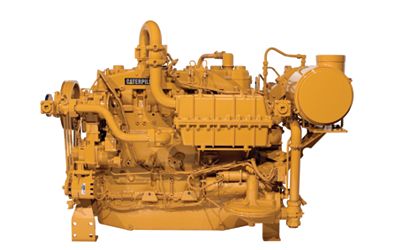

Caterpillar

G3412 Gas Compression Engine

Tough and durable, built on the industry-standard G3400 platform bring maximum uptime and low operating cost to your operation. G3412 engines meet the most demanding continuous duty gas compression applications with virtually no unscheduled downtime. Ideal applications for G3412 engines include gas lift, gas gathering, and wellhead gas compression. Cat G3412 gas engine. Ratings: 448 bkW (600 bhp) @ 1800 rpm are available for non-regulated areas.

Media

Photos

Documents

Details

Specifications

Engine Specifications

| Spec | Value |

|---|---|

| Maximum Rating | 600 BHP 447 bkW |

| Rated Speed | 1800 rpm 1800 rpm |

| Emissions | Rich Burn: Standard Emissions for Export Only Rich Burn: Standard Emissions for Export Only |

| Minimum Rating | 600 BHP 448 bkW |

| Displacement | 1649 in³ 27 l |

| Compression Ratio | 9.7:1 9.7:1 |

| Aspiration | Turbocharged - Aftercooled Turbocharged - Aftercooled |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 0 SAE No. 0 |

| Flywheel Teeth | 136 136 |

| Weight – Dry | 4720 lb 2141 kg |

| Oil Change Interval | 750 hours 750 hours |

| Ignition, Protection | Altronic III Altronic III |

| Stroke | 6 in 152 mm |

| Bore | 5.4 in 137 mm |

Capacity for Liquids

| Spec | Value |

|---|---|

| Cooling System | 20 gal (US) 75.7 l |

| Lube Oil System – Refill | 45 gal (US) 170.3 l |

Standard Equipment

Air Inlet System

- Air cleaner — single element with service indicator

Control System

- Governor — Woodward PSG mechanica

- Governor control — positive locking

Cooling System

- Thermostats and housing

- Jacket water pump

- Aftercooler water pump

- Aftercooler core

Exhaust System

- Watercooled exhaust manifolds

- Dry exhaust elbow

Flywheel & Flywheel Housing

- SAE No. 0 flywheel

- SAE No. 0 flywheel housing

- SAE standard rotation

Fuel System

- Gas pressure regulator

- Natural gas carburetor

Ignition System

- Digital ignition system

Instrumentation

- Service meter

Lube System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Auxiliary oil reservoir

- Rear sump oil pan

- Oil filler in valve cover and dipstick — RH

Mounting System

- Engine supports

Protection System

- Shutoff

General

- Paint — Cat yellow

- Crankshaft vibration damper and drive pulleys

- Lifting eyes

Optional Equipment

Air Inlet System

- Air cleaner

- Air inlet adapter

- Precleaner

- Air cleaner rain cap

Charging System

- Battery chargers

- Charging alternators

- Ammeter gauge

- Ammeter gauge and wiring

- Control mounting

Control System

- EG3P/2301A speed control governor

- PSG electric governor

- PSG pneumatic governor

Cooling System

- Radiators

- Blower fan and fan drives for customer suppliedradiators

- ATAAC conversion

- Aftercooler

- Expansion tank

- Heat exchanger

Exhaust System

- Flexible fittings

- Elbows

- Flanges

- Rain caps

- Mufflers

Fuel System

- Dual gas regulator

- Low energy fuel carburetor

- Low pressure gas conversion

- Propane and natural gas valve and jet kits

- Fuel filter

Ignition System

- CSA ignition

- Ignition ground wiring harness

- Power supply — digital ignition system

Instrumentation

- Alarm module

- Gauges and instrument panels

Lube System

- Auxiliary oil reservoir removal

- Lubricating oil

Mounting System

- Vibration isolators

Power Take-Offs

- Auxiliary drive pulleys

- Enclosed clutch

- Clutch support

- Front stub shaft

- Flywheel stub shaft

- Pulley removal

Protection System

- Gas valves

- Status control box interconnect wiring harness

Starting System

- Air starting motor

- Electric air start control

- Air pressure regulator

- Air silencer

- Electric starting motors — single 24-volt

- Starting aids

- Battery sets (24-volt dry), cables, and rack

General

- Tool set

- Digital diagnostic tool

G3406

G3406

G3408

G3408

G3408C

G3408C

G3412C

G3412C