Main content

Caterpillar

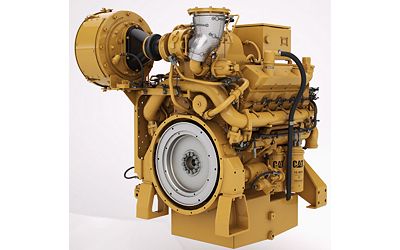

CG137-12 Gas Engine

Tough and durable, with field-proven head design to maximize time between overhauls. CG137 engines are equipped with ADEM A4 technology that brings performance, uptime, and low operating cost to your operation. CG137 engines meet the most demanding continuous duty gas compression applications with virtually no unscheduled downtime. Ideal applications for CG137-12 engines include gas lift, gas gathering, and wellhead gas compression. Cat CG137-12 gas engine. Ratings: 447 bkW (600 bhp) @ 1800 rpm are NSPS site compliant capable with Caterpillar air-fuel ratio control and aftertreatment.

Media

Photos

360° View

Exterior

360° Exterior view. Double click on the image to zoom in on any area of the product.

Documents

Details

Specifications

Engine Specifications

| Spec | Value |

|---|---|

| Maximum Rating | 600 BHP 447 bkW |

| Rated Speed | 1800 rpm 1800 rpm |

| Emissions | Rich Burn: EPA NSPS Site Compliant Capable with Caterpillar Supplied AFRC and Customer Supplied Aftertreatment Rich Burn: EPA NSPS Site Compliant Capable with Caterpillar Supplied AFRC and Customer Supplied Aftertreatment |

| Minimum Rating | 600 BHP 447 bkW |

| Compression Ratio | 8.3:1 8.3:1 |

| Aspiration | Turbocharged - Aftercooled Turbocharged - Aftercooled |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 14 or 18, Flywheel Housing SAE No. 0 SAE No. 14 or 18, Flywheel Housing SAE No. 0 |

| Flywheel Teeth | 136 136 |

| Displacement | 1648 in³ 27 l |

| Oil Change Interval | 750 hours 750 hours |

| Ignition, Protection | Electronic ADEM A4 Electronic ADEM A4 |

| Air/Fuel Ratio Control | Electronic ADEM A4 Electronic ADEM A4 |

| Stroke | 6 in 152.4 mm |

| Bore | 5.4 in 137.2 mm |

| Length | 80.19 in 2036.9 mm |

| Width | 59.65 in 1515.1 mm |

| Height | 66.97 in 1701 mm |

| Weight – Dry | 6250 lb 2835 kg |

Capacity for Liquids

| Spec | Value |

|---|---|

| Cooling System | 20 gal (US) 75 l |

| Lube Oil System – Refill | 45 gal (US) 170 l |

Standard Equipment

Air Inlet System

- Air cleaner — single element with service indicator

- Optional air inlet adapter and rain cap — recommended for weather protection

Control System

- ADEM A4

- Class 1, Division 2, Group C&D and Zone 2

Cooling System

- Jacket water thermostats and housing — full open temperature 98°C (208°F)

- Jacket water pump — gear driven, centrifugal, non-self-priming

- Aftercooler water pump — gear driven, centrifugal, non-self-priming

- Aftercooler core — for treated water and sea air atmosphere

Exhaust System

- Exhaust manifolds — watercooled

- Exhaust elbow — dry 203 mm (8 in)

- Three-way catalyst — 1.0 g NOx and 0.5 g NOx NTE options

Flywheels & Flywheel Housings

- Flywheel, SAE No. 14 or 18

- Flywheel housing, SAE No. 0

- SAE standard rotation

Fuel System

- Air/fuel ratio control

- Gas pressure regulator

- Natural gas carburetor

Lube System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil filler in valve cover, dipstick — RH

Mounting System

- Engine mounting rails — 254 mm (10 in) industrialtype, entire length

Protection System

- ADEM A4 protection

- The following include alarm and shutdown:

- The following is display only

General

- Paint, Caterpillar yellow

- Crankshaft vibration damper and drive pulleys

- Lifting eyes

- Cylinder block inspection covers

Optional Equipment

Charging Alternator

- 24V, 35A CSA alternator

Exhaust System

- Exhaust flex fitting

- Exhaust elbow

- Exhaust flange — ANSI

Instrumentation

- Operator interface panel

- Operator interface panel enclosure

- 15′, 20′, 50′ interconnect harness

Starting System

- Air pressure regulator

- Air start silencer

- Vane starter

- Electric starter

- Turbine starter

Fuel System

- Fuel filter

Air Inlet System

- Precleaner

- Rain cap

CG137-8

CG137-8