Main content

Caterpillar

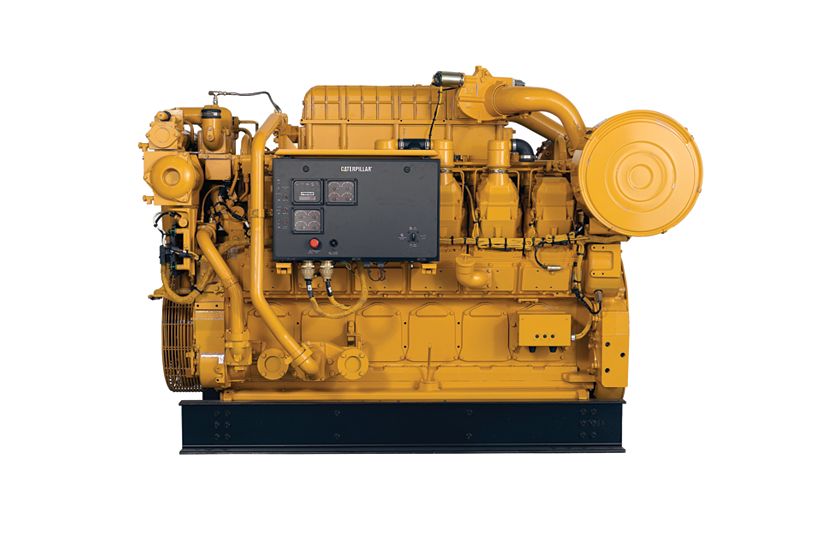

3512C (HD) Land Mechanical Drilling Engine

Cat 3512C (HD) engines set the standard in the drilling industry. For many years the 3500 has been the preferred choice by drillers due to their high performance, durability, and reliability in the oilfield while maintaining low emissions.The ideal application for the 3512C (HD) engine is mechanical drive for land drilling rigs.Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. 3512C (HD) engines, with ratings: 932-1100 bkW (1250-1475 bhp) @ 1200 rpm meet U.S. EPA Non-road Tier 2 equivalent and CARB Tier 2 equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Media

Photos

Details

Specifications

Engine Specifications

| Spec | Value |

|---|---|

| Maximum Rating | 1475 BHP 1100 bkW |

| Emissions | U.S. EPA Non-road Tier 2 U.S. EPA Non-road Tier 2 |

| Displacement | 3574 in³ 59 l |

| Minimum Rating | 1250 BHP 932 bkW |

| Bore | 6.69 in 170 mm |

| Stroke | 8.46 in 215 mm |

| Rated Speed | 1200 r/min 1200 r/min |

| Aspiration | Turbocharged-Aftercooled Turbocharged-Aftercooled |

| Governor and Protection | ADEM A3 ADEM A3 |

| Engine Weight – Net Dry | 11945 lb 5423 kg |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Oil Change Interval | 500 500 |

| Flywheel and Flywheel Housing | SAE No. 00 SAE No. 00 |

| Flywheel Teeth | 183 183 |

Capacity for Liquids

| Spec | Value |

|---|---|

| Minimum Cooling System – Engine Only | 41 gal (US) 157 l |

Dimensions

| Spec | Value |

|---|---|

| Length | 105.6 in 2682 mm |

| Width | 70.5 in 1791 mm |

| Height | 79.5 in 2019 mm |

Standard Equipment

Air Inlet System

- Separate circuit aftercooler core — corrosion resistant coated (airside), air cleaner (single element w/service indicator)

- Dual rear-mounted turbochargers

Control System

- ADEM A3 ECU — LH

- Electronic fuel injector fuel system (10 amp DC power required todrive electronic engine control unit)

Cooling System

- Torque converter connections

- Thermostats and housing, jacket water pump, gear-drivencentrifugal

- Connections for radiator cooling

- Dual outlets: 88.9 mm O.D. (3.5 in) elbow hose connections

- Separate Circuit Aftercooler (SCAC)

Exhaust System

- Exhaust manifold — dry, stainless steel bellows

- Dual turbochargers with watercooled bearings

- Exhaust outlet: 292 mm I.D. (11.5 in), 12-10.5 mm dia. holes EQ SP,376 mm bolt hole dia.

Flywheels and Flywheel Housing

- Flywheel, SAE No. 0 — 151 teeth

- Flywheel housing — SAE No. 0

Fuel System

- Primary fuel filter

- Fuel priming pump

- Fuel filter — RH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

Instrumentation

- Electronic instrument panel

- Instrumentation readouts:

Lube System

- Crankcase breather — top-mounted

- Oil cooler

- Oil filler and dipstick — RH

- Oil pump

- Oil filter — RH spin-on type

- Rear sump oil pan, 250-hour change interval

- Oil pan drain valve — 3/4″ NPT female connection

Mounting System

- Rails — mounting, floor type

Power Take-Offs

- Front housing — two-sided

Protection System

- ADEM A3 ECU system to provide customer-programmableengine deration strategies to protect against adverse operatingconditions

- Emergency stop logic inputs provided at 40-pin customer interfaceconnection

- Air inlet shutoff

Starting System

- Air starting motor — RH, 620 to 1034 kPa (90 to 150 psi)

- Air silencer

General

- Paint — Cat yellow

- Vibration damper and guard

- Lifting eyes

- B-Series LAND

Optional Equipment

Air Inlet System

- Air cleaner and air cleaner mounting

- Remote air inlet adapters

- Air inlet heater

Charging System

- Battery chargers

- Charging alternators

Control System

- Local speed throttle control

- Throttle position sensors

- Load sharing modules

- Governor conversion

Cooling System

- High gloss black folded core radiators

- Coolant regulator conversion

- Belt guard and radiator guard

- Blower fan

- Radiator cover

- Fan drive and fan pulleys

- Water level switch gauge

- Coolant level sensors

- Coolant conditioner

- Expansion tank

- Heat exchanger cooling conversion

- Auxiliary water pump

- Air separator

Exhaust System

- Flexible exhaust fitting

- Elbows and flange

- Flange and exhaust adapters

- Manifold and mufflers

Fuel Systems

- Flexible fuel lines

- Fuel cooler

- Water/fuel separator

- Fuel level switch

Instrumentation

- Customer management device

- Remote panel display and remote cylinder temperature display

- Switches and contactors

- Gauges and instrument panels

Lube System

- Fumes disposal

- Oil pans

- Prelube options

- Sump pumps

- Oil Filters

Mounting System

- Vibration isolators

Power Take-Offs

- Front housing

- Flexible couplings

- Coupling hub

- Front accessory drives

- Auxiliary drive shaft

- Auxiliary drive pulleys

- Front stub shaft

- Damper guard removal

- Pulleys

- Flywheel stub shaft

Protection System

- Shutoffs

- Switches and contractors

- Explosion relief valve

- Sensors

- Oil pressure monitor

- Shutoff controls

- Corrosion protection

Starting System

- Air starting motors — electric

- Air pressure regulator

- Air silencer

- Air start controls — manual, electric

- Redundant start

- Starting aids

- Battery sets – 24V

- Battery cable and battery rack