Main content

Caterpillar

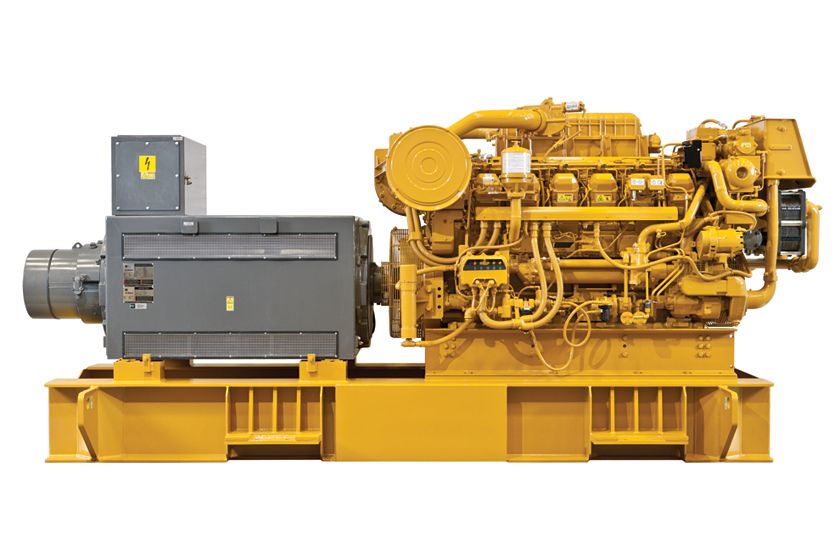

3512C (HD) Offshore Generator Set

Cat 3500 offshore generator sets are specifically designed for drilling and production operations offshore. Decades of experience powering offshore vessels and platforms make have evolved into a product that offers proven performance, low emissions, high durability, and low owning and operating costs. Applications for 3500 offshore generator sets include main power, essential services power, and emergency power on-board drilling and production rigs and vessels. Cat generator sets are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. Cat 3512C (HD) offshore generator set. Ratings: 1550-1700 ekW (1938-2125 kVA) @ 60 Hz (1800 rpm). Meets IMO Tier II emission standards.

Media

Photos

Documents

Details

Specifications

Engine Specifications

| Spec | Value |

|---|---|

| Minimum Rating | 1938 kV·A 1550 ekW |

| Maximum Rating | 2125 kV·A 1700 ekW |

| Emissions | IMO Tier II IMO Tier II |

| Displacement | 3574 in³ 59 l |

| Bore | 6.7 in 170 mm |

| Engine Control | ADEM A3 ADEM A3 |

| Stroke | 8.5 in 215 mm |

| Fuel System | EUI EUI |

| Weight | 33300 lb 14975 kg |

| Aspiration | Turbocharged-Aftercooled Turbocharged-Aftercooled |

| Oil Change Interval | 1000 h 1000 h |

Dimensions

| Spec | Value |

|---|---|

| Width | 71.9 in 1825 mm |

| Length | 214.5 in 5448 mm |

| Height | 91 in 2313 mm |

Capacity for Liquids

| Spec | Value |

|---|---|

| Cooling System – Engine | 41.5 gal (US) 157 l |

| Lube Oil System – Refill | 84 gal (US) 318 l |

Standard Equipment

AIR INLET SYSTEM

- Corrosion resistant separate circuit aftercooler core, regular dutyair cleaners, dual turbochargers

CONTROL SYSTEM

- Caterpillar A-III electronic engine control, Electronic UnitInjection fuel system, rigid wiring harness

COOLING SYSTEM

- Auxiliary fresh water pump, centrifugal non-self-priming auxiliarysea water pump, gear driven centrifugal jacket water pump,expansion tank, engine oil cooler, thermostats and housing

EXHAUST SYSTEM

- Dry gas-tight exhaust manifolds with heat shields, dualturbochargers with water-cooled bearings and heat shields,vertical exhaust outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel, SAE No. 00, 183 teethFlywheel housing, SAE No. 00

FUEL SYSTEM

- Fuel filter, RH, with service indicators

- Fuel transfer pump

- Electronically Controlled Unit Injectors

INSTRUMENTATION

- Engine mounted instrument panel with four position switch, overspeed shutdown notification light, emergency stop notificationlight, graphical display unit for analog or digital display of: oil andfuel pressure, oil and fuel filter differential, system DC voltage,exhaust and water temperature, air inlet restriction, servicemeter, engine speed, fuel consumption (total and instantaneous)

LUBE SYSTEM

- Top mounted crankcase breather, RH oil filter, RH oil filler,gear type oil pump, deep sump oil pan, recommended use ofCaterpillar Diesel Engine Oil 10W30 or 15W40

MOUNTING SYSTEM

- Industrial type engine mounting rails)

POWER TAKE-OFFS

- Accessory driveLower RH, Lower LHFront housing, Two-sided

PROTECTION SYSTEM

- A-III Electronic Monitoring System provides customer programmableengine de-ration strategies to protect against adverse operatingconditions

- Emergency stop push button (located in Electronic Instrument Panel)Safety shutoff protection for oil pressure and water temperature, overspeed protection

GENERAL

- Vibration damper and guardPaint, Caterpillar Yellow engine with black rails.Lifting eyes

Optional Equipment

AIR INLET SYSTEM

- Air Cleaner Removal

- Remote Air Inlet Adapters

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

CONTROL SYSTEM

- Load Sharing module

- Local speed throttle control

COOLING SYSTEM

- Water level switch gauge

- Coolant level sensors

- Connections

- Keel Cooling Conversions

- Radiator cooling conversion

- Heat exchangers

- Auxiliary water pumps

- Sea water pump removal

- Air separator

EXHAUST SYSTEM

- Exhaust outlet

- Flexible fittings

- Elbows

- Flanges

- Flange and exhaust expanders

- Mufflers

FUEL SYSTEM

- Fuel Cooler

- Fuel priming pumps

- Flexible fuel lines

- Rigid Fuel Lines

- Primary fuel filter

- Fuel level switch

GENERATORS AND GENERATOR ATTACHMENTS

- INSTALLED GENERATOR ARRANGEMENTS F/MAR AUX ENGINES

- INSTALLED GENERATOR ARRANGEMENTS F/MAR AUX ENGINES

INSTRUMENTATION

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface Box

- Thermocouples

- Remote panel display

- Remote cylinder temperature display

LUBE SYSTEM

- Oil Pan

- Oil pan accessories

- Sump pumps

- Prelubrication Options

- Lubricating oil

- Centrifugal Oil Filter

MOUNTING SYSTEM

- Vibration isolators

- Rails

POWER TAKE-OFFS

- Flywheel guard

- Flexible coupling

- Coupling hub

- Front housing accessories

- Upper left hand front location

- Upper left hand rear location

- Upper right hand front location:

- Upper right hand rear location

- Lower left hand front location

- Front housing accessory drives

- Front power take-offs

- Crankshaft pulleys

- Damper guard removals

PROTECTION SYSTEM

- Air inlet shutoffs

- Switches and contactors

- Explosion relief valve

- Sensors

SPARE PART KITS

- Engine Parts Kits

STARTING SYSTEM

- Starting motors or barring divice

- Air starting motors options

- Starting aids

- Battery sets – 24 volt – Dry

- Battery rack

GENERAL

- Tool set

- Caterpillar datalink wire

SVCE TOOLS/SHIP PROT/FACTORY SUPPORT

- Commissioning