Main content

Cat® Machine Rebuild services

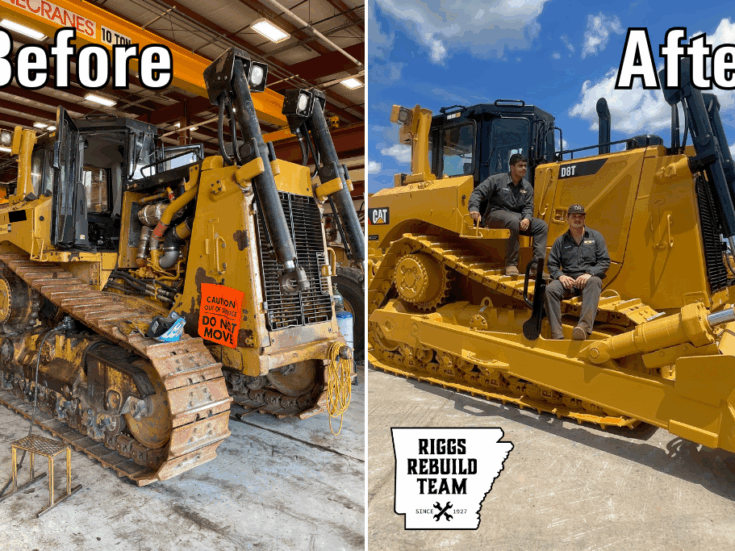

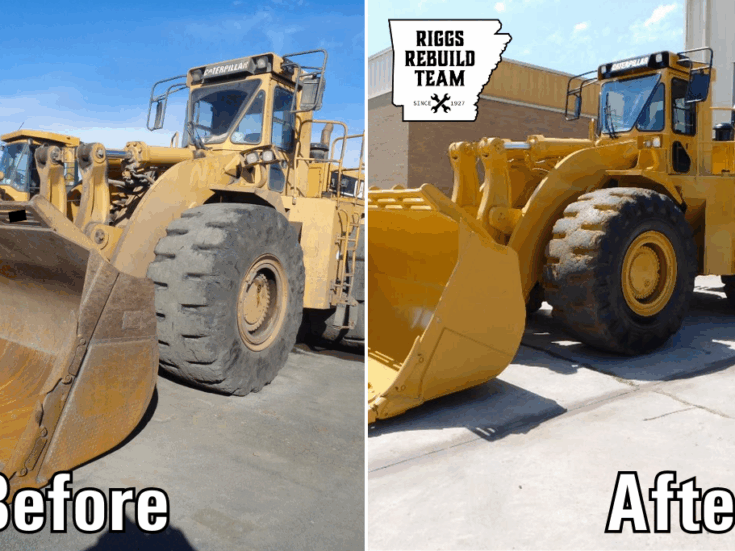

Giving Your Machine a Second Life

Breathe new life into your equipment. A Cat Machine Rebuild from Riggs Cat restores your machine’s core systems including radiator, engine, transmission, torque converter, final drive, and axle to factory-grade performance. Rigorous testing, engineering upgrades, and thousands of replacement parts ensure reliability and value for years to come.

What’s Included

Approximately 200 tests and inspections of the powertrain components are performed as well as the replacement or reconditioning of approximately 3,000 parts, including:

- Powertrain electrical switches

- Sensors

- Sending units

- Electronic control modules

- Engine wiring harnesses

- Bearings

- Gaskets

- Seals

- Coolant hoses

Warranty & Custom Repair Options

Engine and drive trains are critical to productivity and have a major impact on ownership and operating costs. Making sure they are working at peak performance is important not only to your equipment, but to your entire operation.

Tailored repairs are developed based on your specific equipment needs and unique business circumstances. You can get a lot of life out of your Genuine Cat parts as they are built to be rebuilt. By taking advantage of their reusability, you can maximize the life and value of your machines.

We will walk you through a series of questions to determine four factors which will help you decide on a repair option: length of ownership, utilization, affordability and turnaround time. From there, you can make an informed decision based on what’s best for your business.

It’s important to repair components before they fail because repairing them after failure can cost anywhere from two to three times more.

The Certified Rebuild Process: Built for Reliability

The Certified Rebuild process incorporates the latest critical engineering updates, improvements, tests and more to ensure top-notch performance of your rebuild.

Engineering Updates

During reassembly, critical improvements that have been made to this machine model since original manufacturing will be incorporated into the powertrain.

Powertrain Tests

The engine, fuel system, transmission, torque converter, differential, final drives and radiators are:

- Disassembled

- Inspected

- Reconditioned with new or Remanufactured Genuine Cat parts

Before reinstallation, each component is thoroughly bench tested. Internal hard parts or castings not meeting reusability will be an additional cost.

Reassembly

All critical torques, clearances and pressure settings are maintained and recorded during careful reassembly of your powertrain by our technicians. Powertrain harnesses and ECMs are always replaced.

Performance Testing

Quality control is an important part of the Certified Rebuild program, so testing is conducted at several stages. Tests performed include but not limited to:

- Turbocharger boost

- Throttle response

- Stall speed RPM

- Transmission and steering clutch response

Contamination control procedures are followed to ensure the ISO 18/15 standards for system cleanliness are met. Instrument and operational testing are also conducted to ensure field performance levels match those in the shop.

Client Evaluation

The rebuild process is not considered complete until clients’ operators are satisfied with the performance of the powertrain in its working environment.

Why Opt for a Cat Machine Rebuild?

-

Restores like-new performance with factory-level quality

-

Incorporates crucial design and engineering updates

-

Delivers cost-effective long-term value vs. replacement

-

Includes warranty and personalized service options

-

Equipped to extend machine life and maximize uptime

Take the Next Step

Let’s bring your machine back to its best form with our Cat Machine Rebuild Services.